Izigxobo zokukhanya ezihlanganisiweziyingxenye ebalulekile yengqalasizinda yasemadolobheni, zihlinzeka ngokukhanya emigwaqweni, emapaki nasezindaweni zomphakathi. Njengomhlinzeki wezinsika zokukhanyisa ezikhanyisiwe ohamba phambili, iTianxiang izibophezele ekuhlinzekeni ngemikhiqizo esezingeni eliphezulu ehlangabezana nezidingo ezahlukahlukene zamakhasimende. Kulesi sihloko, sizohlola inqubo yokukhiqiza izinsika zokukhanyisa ezikhanyisiwe, sigqamise ukubaluleka kokufaka izinsika kanye nezinzuzo ezikulethelayo.

Ukuqonda i-Galvanizing

Ukugaya nge-galvanizing kuyinqubo emboza insimbi noma insimbi ngesendlalelo se-zinc ukuvimbela ukugqwala. Lokhu kugqoka okuvikelayo kubalulekile ezinsikeni zokukhanya, ezivame ukuchayeka ezimweni zezulu ezinzima, okuhlanganisa imvula, iqhwa, kanye namazinga okushisa aphezulu. Inqubo yokugaya nge-galvanizing ayigcini nje ngokwandisa impilo yezinsikeni zokukhanya, kodwa futhi inciphisa nezindleko zokulungisa, okwenza kube inketho engabizi kakhulu komasipala kanye namabhizinisi.

Inqubo yokukhiqiza isigxobo sokukhanya esikhanyisiwe

Ukukhiqizwa kwezinsika zokukhanyisa ezihlanganisiwe kuhilela izinyathelo eziningana ezibalulekile, ngasinye esithinta ukuqina nokusebenza komkhiqizo wokugcina. Nansi incazelo eningiliziwe yokuthi izinsika zokukhanyisa ezihlanganisiwe zenziwa kanjani:

1. Ukukhetha izinto

Isinyathelo sokuqala ekwenzeni izinti zokukhanyisa ezikhanyisiwe ukukhetha izinto ezifanele. Insimbi esezingeni eliphezulu ivame ukusetshenziswa ngenxa yamandla ayo nokuqina kwayo. Insimbi itholakala kubaphakeli abathembekile ukuqinisekisa ukuhambisana nezindinganiso zemboni. Kwa-Tianxiang, sibeka phambili ikhwalithi yezinto zokusetshenziswa ukuqinisekisa ukuthi izinti zethu zokukhanyisa ezikhanyisiwe zihlala isikhathi eside.

2. Ukusika nokubumba

Uma insimbi isikhethiwe, iyasikwa ibe nobude nesimo esifiselekayo. Le nqubo ingase ihilele ukusetshenziswa kwemishini ethuthukisiwe ukuqinisekisa ukunemba nokuvumelana. Izingodo zokukhanya zingaklanywa ngokuphakama nobubanzi obuhlukahlukene, kuye ngokuthi zihloselwe ukusetshenziswa kanjani. Isibonelo, ingodo yokukhanya yasemgwaqweni ingaba yinde kunengodo yokukhanya esetshenziswa epaki noma endaweni yokuhlala.

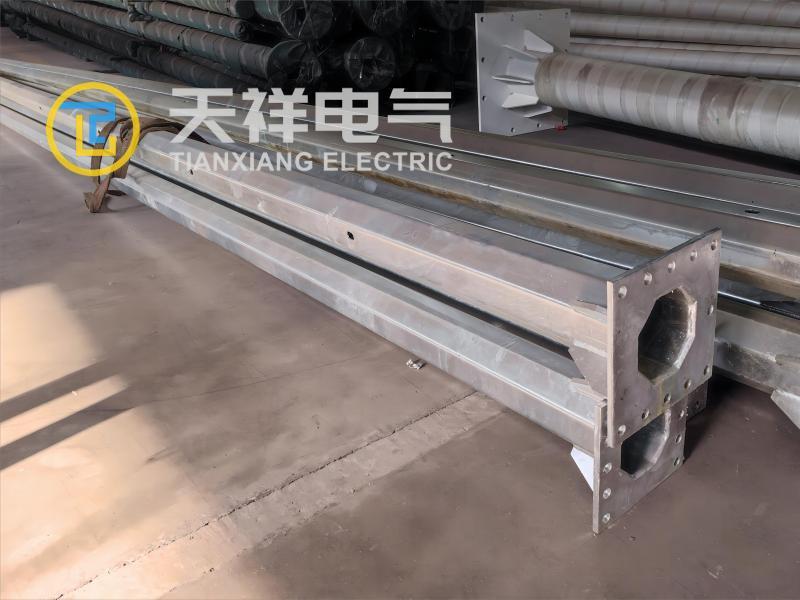

3. Ukushisela nokuhlanganisa

Ngemva kokusika, izingxenye zensimbi ziyahlanganiswa ukuze zakhe isakhiwo sesigxobo sokukhanya. Lesi sinyathelo sibalulekile njengoba siqinisekisa ukuthi isigxobo sokukhanya siqinile futhi singamelana nokucindezeleka kwemvelo. Abashiseli abanekhono baseTianxiang basebenzisa ubuchwepheshe obuthuthukisiwe ukudala amalunga aqinile athuthukisa ubuqotho besigxobo sokukhanya.

4. Ukulungiswa kwendawo

Ngaphambi kokufaka i-galvanizing, izinti zikagesi zidlula enkambisweni yokulungisa ubuso ukuze kususwe noma yikuphi ukungcola okufana nokugqwala, uwoyela noma ukungcola. Lesi sinyathelo sibalulekile ukuqinisekisa ukuthi uqweqwe lwe-zinc lunamathela kahle ensimbini. Inqubo yokulungisa ubuso ngokuvamile ihilela ukuhlanza izinti ngezindlela ezifana nokuqhuma kwe-grit noma ukuhlanza ngamakhemikhali.

5. Ukuhlanganisa nge-galvanizing

Inhliziyo yenqubo yokukhiqiza i-galvanizing. Izingodo ezilungisiwe zicwiliswa ebhavini le-zinc encibilikisiwe ekushiseni okungaba ngu-450 degrees Celsius. Le nqubo ibangela ukuthi i-zinc isabele nensimbi ensimbini, yakha uchungechunge lwezendlalelo ze-zinc-iron alloy ezinikeza ukumelana okuhle kakhulu nokugqwala. Izingodo zibe sezisuswa ebhavini bese zipholiswa, okuholela ekugqokeni okuqinile okuvikelayo.

6. Ukulawulwa kwekhwalithi

Kwa-Tianxiang, sithatha ukulawula ikhwalithi njengento ebalulekile. Ngemva kokufaka i-galvanizing, i-pole ngayinye ihlolwa ngokucophelela ukuqinisekisa ukuthi ihlangabezana nezindinganiso zethu eziphakeme. Lokhu kuhlanganisa ukuhlola ubukhulu be-zinc coating, ukuhlola ama-weld, nokuqinisekisa ukuthi i-pole ayinamaphutha. Ukuzibophezela kwethu ekhwalithini kuqinisekisa ukuthi i-pole yethu ye-galvanizing ithembekile futhi ihlala isikhathi eside.

7. Ukuqeda izinto

Uma izinti sezidlulile ekulawulweni kwekhwalithi, zingase zidlule ekuqedeni okwengeziwe njengokupenda noma ukwengeza izinto zokuhlobisa. Nakuba ukumbozwa nge-galvanized kunikeza isivikelo esihle kakhulu, amanye amakhasimende angase akhethe umbala noma isiphetho esithile ukuze kuhambisane nezidingo zawo zobuhle. Kwa-Tianxiang, sinikeza izinketho ezenziwe ngokwezifiso ukuze kuhlangatshezwane nezidingo ezihlukile zamakhasimende ethu.

8. Ukupakisha nokulethwa

Ekugcineni, izinsika zokukhanyisa eziqediwe zipakishwa ngokucophelela ukuze zilethwe. Siyaqinisekisa ukuthi zipakishwe kahle ukuze kuvinjelwe umonakalo ngesikhathi sokuthuthwa. Njengomhlinzeki wezinsika zokukhanyisa eziklanyiwe odumile, uTianxiang uzibophezele ekulethweni ngesikhathi, eqinisekisa ukuthi amakhasimende ethu athola ama-oda awo uma ewadinga.

Izinzuzo zezinsika zokukhanya ezihlanganisiwe

Izigxobo zokukhanya ezihlanganisiwe zinikeza izinzuzo eziningi ezenza kube ukukhetha okuthandwayo kwezicelo ezahlukahlukene:

Imelana Nokugqwala: Isembozo se-zinc sivikela insimbi ekugqwaleni nasekugqwaleni, sandisa isikhathi sokuphila kwesigxobo.

Ukulungiswa Okuphansi: Izigxobo ze-galvanized zidinga ukulungiswa okuncane, okunciphisa izindleko zesikhathi eside komasipala namabhizinisi.

Ukuqina: Ukwakhiwa okuqinile kwezinsika zokukhanyisa ezenziwe nge-galvanized kuqinisekisa ukuthi zingakwazi ukumelana nezimo zezulu ezinzima kanye nokusetshenziswa njalo.

Ukukhanga Kobuhle: Izigxobo zokukhanya ezifakwe i-galvanized zinezinketho eziningi zokwenza ngokwezifiso ukuze kuthuthukiswe ukukhanga okubonakalayo kwezindawo zomphakathi.

Ekuphetheni

Ngamafuphi, iinqubo yokukhiqiza izigxobo zokukhanya ezikhanyisiwekuhilela izinyathelo eziningana ezibalulekile, kusukela ekukhetheni izinto kuya ekugayweni kwe-galvanizing kanye nokulawulwa kwekhwalithi. Njengomhlinzeki wezinsika zokukhanyisa ezikhanyisiwe ohamba phambili, iTianxiang iyaziqhenya ngokuhlinzeka ngemikhiqizo esezingeni eliphezulu ehlangabezana nezidingo zamakhasimende. Uma ufuna izinsika zokukhanyisa ezikhanyisiwe eziqinile nezithembekile, sikumema ukuthi usithinte ukuze uthole isilinganiso. Ithimba lethu likulungele ukukusiza ekutholeni ikhambi elifanele izidingo zakho zokukhanyisa.

Isikhathi sokuthunyelwe: Disemba-26-2024