Umuntu kumele aqale ngemininingwane ejwayelekile ukuze ahlole ukuthi ngabeisigxobo somgwaqo selangakungumkhiqizo ofanelekayo.

Izigxobo zomgwaqo zelanga zivame ukuncishiswa. Umshini wokusika amapuleti usetshenziselwa ukuwasika abe amapuleti e-trapezoidal ngokwezilinganiso zawo ezihambisanayo, kanti umshini wokugoba usetshenziselwa ukuwagoqa abe yishubhu elincishisiwe. Uma uhlola ikhwalithi yawo, khumbula la maphuzu alandelayo:

1. Kuzoba khona ijoyinti epayipini eligoqiwe eligoqiwe ngemva kokuba ipuleti lensimbi ligobile. Leli joyinti lidinga ukuvalwa kusetshenziswa umshini wokushisela we-arc ongaphansi komhlaba. Lokhu kushisela kubaluleke kakhulu. Uma ama-roller omshini wokushisela we-arc ongaphansi komhlaba engavumelanisiwe, amapuleti ensimbi ezinhlangothini zombili azobe engalingani, okuthinta ukubukeka. Qaphela ukushisela kwe-pinholes. Uma kukhona i-pinholes, ngisho nangemva kokushisela nge-galvanizing kanye nokumbozwa nge-powder, ukugqwala endaweni ye-pinhole kusalokhu kungenakugwenywa.

2. Ukushisela e-flange kanye ne-power supply port kumele kube ngokulinganayo futhi kube bushelelezi. Njengoba lonke ukusekelwa kwe-solar street pole kuncike phansi, i-weld joint kumele ibe banzi futhi ingabi nazikhala. Njengoba i-weld slag eningi ivame ukuchaphazwa ngesikhathi sokushisela i-flange ngesandla, ukuhlanza ngokucophelela kubalulekile ukuze kugwenywe umonakalo omkhulu wobuhle.

Ngokuvamile, kusetshenziswa izikulufo ezimbili ukubopha ingalo yensika yelanga ensika. Ukuqinisekisa ukucaca kwembobo yentambo phakathi kwengalo nensika kubalulekile. Abanye abakhiqizi bezinsika zokukhanya basebenzisa ukusika ilangabi ukwenza imbobo yentambo bezama ukonga isikhathi nomzamo. Lokhu kubangela ukuthi i-weld slag izungeze udonga lwangaphakathi lwembobo, okwenza ukufakwa endaweni kube nzima futhi kudle isikhathi.

3. Hlola i-galvanization yesigxobo somgwaqo selanga. Ubukhulu besendlalelo se-galvanized kufanele bufane. Ubukhulu obungalingani esigxotsheni esisodwa, nakuba kungeyona inkinga enkulu, kubonisa iphutha enqubweni ye-galvanization. Futhi, hlola ukukhanya. I-galvanization enhle izoba nokukhanya kwesiliva ngaphansi kokukhanya kwelanga; ubuso obufiphele, obungenakukhanya bubonisa umkhiqizo ongaphansi kwesilinganiso ozogqwala ngokushesha.

4. Ukufakwa kwempuphu kuyisinyathelo sokugcina ekukhiqizweni kwensika yesitaladi yelanga esiqediwe. Amandla ayo okumelana nokugqwala alandela ukugaya, kodwa futhi abalulekile. Inqubo enhle yokufakwa kwempuphu ibukeka ibushelelezi futhi ifana, ngaphandle kwamabala aphuthelwe, futhi uma uhlolisisa kahle, azikho izimpawu zokushintsha umbala. Ukuze uhlole ukunamathela kwensika yempuphu esigxotsheni, ungasebenzisa i-tip yensimbi ebukhali ukuze uklwebhe umugqa ngamandla endaweni engabalulekile, njengangaphansi kwe-flange. Bheka ukuthi noma yikuphi ukufakwa kwempuphu kuyaphakama yini ohlangothini ngalunye lokuklwebheka. Uma kungenjalo, ukunamathela kuyamukeleka. Uma kukhona ukuphakamisa, kubonisa inkinga ngenqubo yokufakwa kwempuphu. Lokhu kungaholela ekuqhekekeni okukhulu kwensika yempuphu ngesikhathi sokuthuthwa, okuthinta ukubukeka futhi kunciphise kakhulu isikhathi sokuphila esingagqwali.

Amaphuzu angenhla awakwazi ukufingqa yonke inqubo, kodwa uma wonke la maphuzu eneliseka, khona-ke i-solar street pole ingabhekwa njengomkhiqizo ofanelekayo.

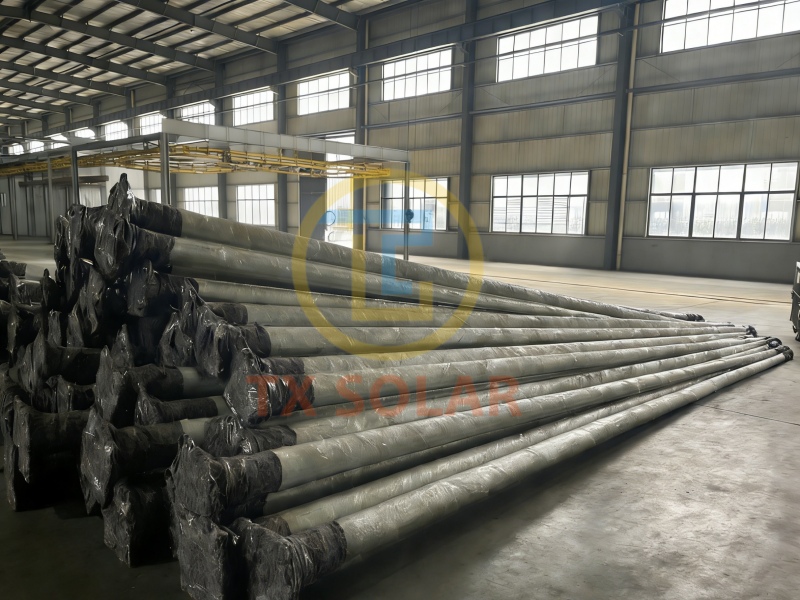

Ifektri Yezibani Zasemgwaqweni yaseTianxiangSekuphele iminyaka engamashumi amabili sithumela izigxobo zokukhanyisa emgwaqweni kwamanye amazwe, futhi zithandwa kakhulu ngamakhasimende aphesheya. Imikhiqizo yethu isekela ukuphakama nobubanzi obufanele, futhi kulula ukuyifaka. Sinikeza amanani ancintisanayo kanye nokulethwa okuzinzile, ngezaphulelo zama-oda amaningi. Simema ngobuqotho osonkontileka bobunjiniyela kanye nabasabalalisi ukuthi babambisane nathi!

Isikhathi sokuthunyelwe: Disemba-23-2025