I-Panel Lamp Pole Yangaphandle I-Street Light Pole Ingalo Ephindwe Kabili Eyodwa

LANDA

IZINTO EZISETSHENZISWAYO

Incazelo

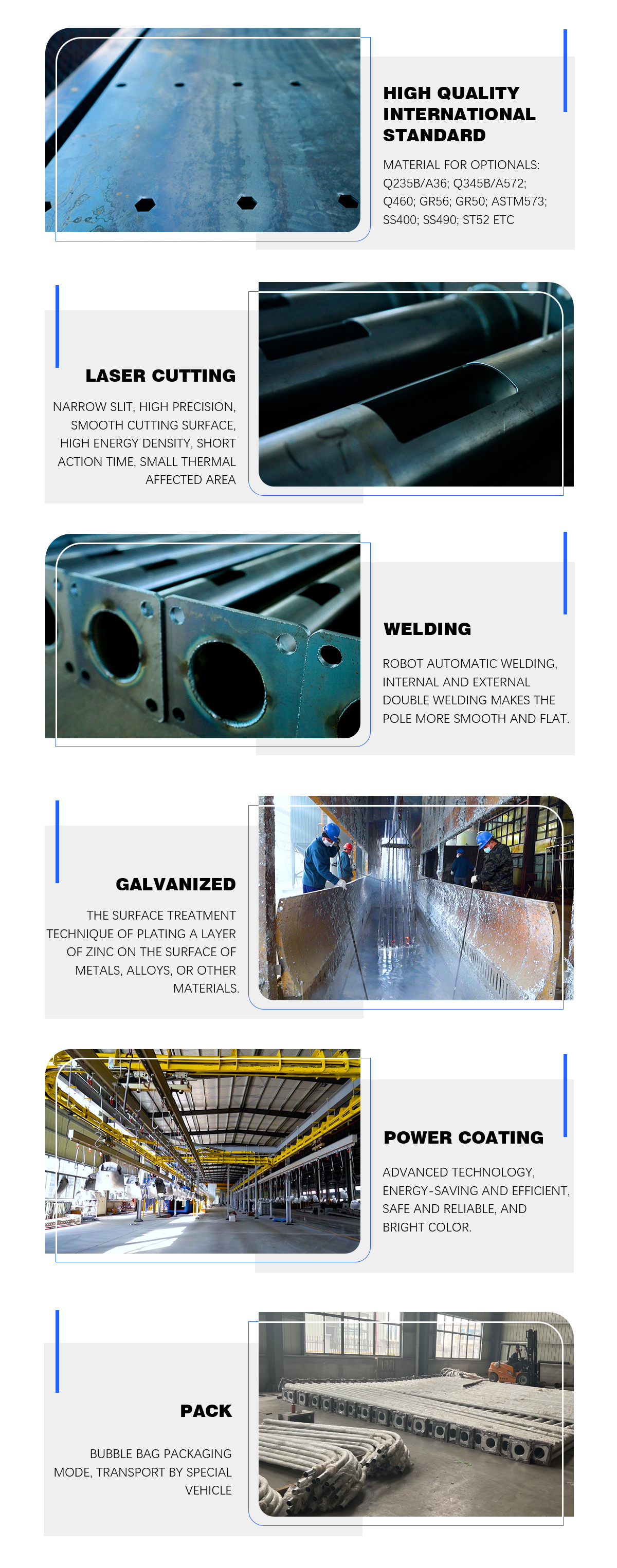

Isibani somgwaqo senziwe kakhulu ngensimbi ye-Q235 esezingeni eliphezulu ngokugoba.

Indlela yokushisela yesigxobo sesibani somgwaqo iwukushisela okuzenzakalelayo kwe-sub-arc.

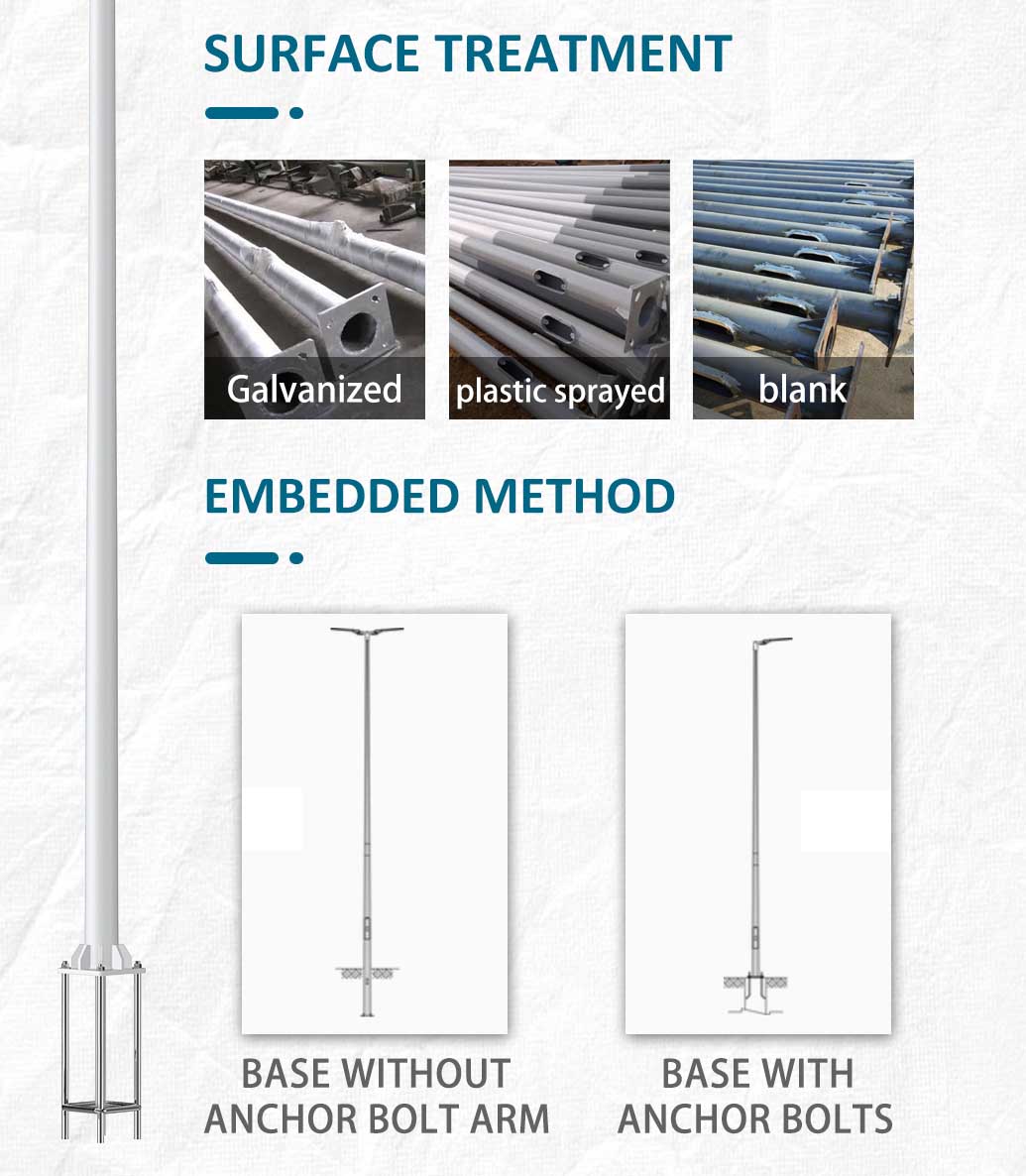

Izigxobo zokukhanyisa emgwaqweni ziyindlela yokwelapha ukugqwala efakwe nge-hot-dip galvanized.

Isibani somgwaqo kufanele sifafazwe ngempuphu yepulasitiki ye-polyester ehlanzekile yangaphandle esezingeni eliphezulu, futhi umbala ungakhethwa ngokukhululekile ngamakhasimende.

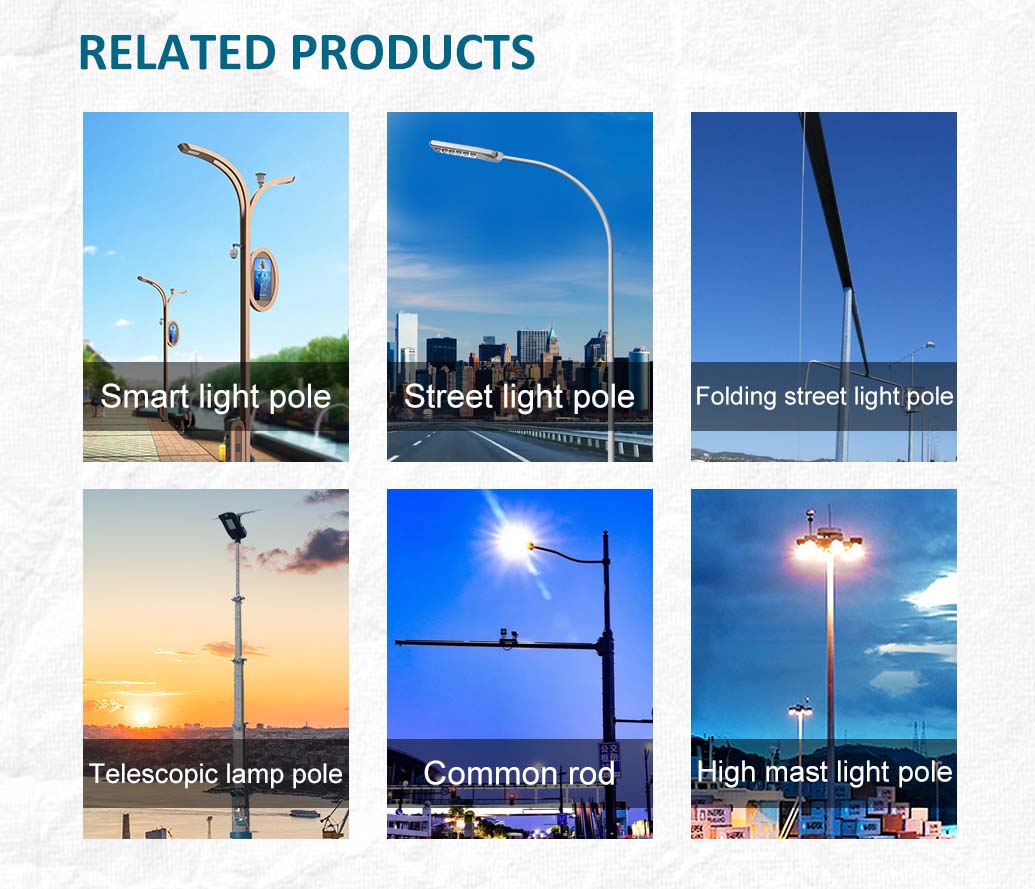

Ngokuthuthuka kwezikhathi, ukusetshenziswa kwezinsika zokukhanya zasemgwaqweni nakho kuyashintsha njalo. Isizukulwane sokuqala sezinsika zokukhanya zasemgwaqweni yinsika esekela umthombo wokukhanya. Kamuva, ngemva kokuba izibani zomgwaqo zelanga zengezwe emakethe, sacabangela indawo evunguza umoya yephaneli yelanga kanye ne-coefficient yokumelana nomoya. Linda, ngibone izibalo eziqinile futhi ngazama kaninginingi. Izibani zomgwaqo zelanga manje seziwumkhiqizo ovuthiwe kakhulu emakethe yezibani zomgwaqo. Kamuva, kunezinsika eziningi kakhulu emgwaqweni. Sihlanganisa izinsika eziseduze, njengezibani zesignali nezibani zomgwaqo. , izimpawu nezibani zomgwaqo sezibe yinsika evamile yamanje, okwenza umgwaqo uhlanzeke futhi ucoceke. Izibani zomgwaqo sezibe ngesinye sezikhungo zomgwaqo ezinesimbozo esikhulu kakhulu. Esikhathini esizayo, iziteshi eziyisisekelo ze-5g nazo zizohlanganiswa nezibani zomgwaqo ukuze zenze isimbozo sesignali sibe sikhulu. Futhi kuyingqalasizinda ebalulekile yobuchwepheshe besikhathi esizayo obungenamshayeli.

Inkampani yethu ibilokhu isebenza ebhizinisini lokukhanyisa imigwaqo cishe iminyaka engama-20. Esikhathini esizayo, sizoqhubeka nokusebenza kanzima kwengqalasizinda yasemadolobheni kanye nebhizinisi lokukhanyisa imigwaqo ukuze sithuthukise indawo yokuhlala futhi sikhuthaze intuthuko yesikhathi.

Izithombe Zomphumela

Inqubo Yokukhiqiza

Izitifiketi Zethu

Umbukiso Wethu

Kungani ukhethe i-HDG pole yethu?

1. Ukumelana nokugqwala:

Izinsika zethu ze-galvanized ezifakwa ngokushisa zinamandla okumelana nokugqwala futhi zilungele ukusetshenziswa ngaphandle ngaphansi kwezimo zezulu ezahlukahlukene.

2. Impilo yenkonzo ende:

Inqubo yethu yokugaya ngogesi ngokushisa yakha ungqimba oluqinile, olungandisa impilo yensika yokukhanya futhi lunciphise isidingo sokufakwa kabusha njalo.

3. Ukugcinwa okuphansi:

Izinsika zethu ze-HDG zidinga ukulungiswa okuncane, okusindisa isikhathi kanye nezinsiza ngokuhamba kwesikhathi.

4. Kuhle:

Ubuso obufanayo nobucwebezelayo bezinsika zethu zokukhanya ze-HDG bungathuthukisa ukubukeka kwezindawo zangaphandle.

5. Ukuzinza kwemvelo:

I-HDG iyindlela yokumboza eqhubekayo enikeza isivikelo sesikhathi eside sezinsika zethu zokukhanya futhi inciphisa umthelela wemvelo wokufakwa kabusha njalo.

6. Ukuphumelela Kwezindleko:

Izinsika zethu ze-HDG zihlala isikhathi eside futhi izidingo zokunakekelwa eziphansi zingaholela ekongeni izindleko ngokuhamba kwesikhathi.

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

Phezulu